产品介绍

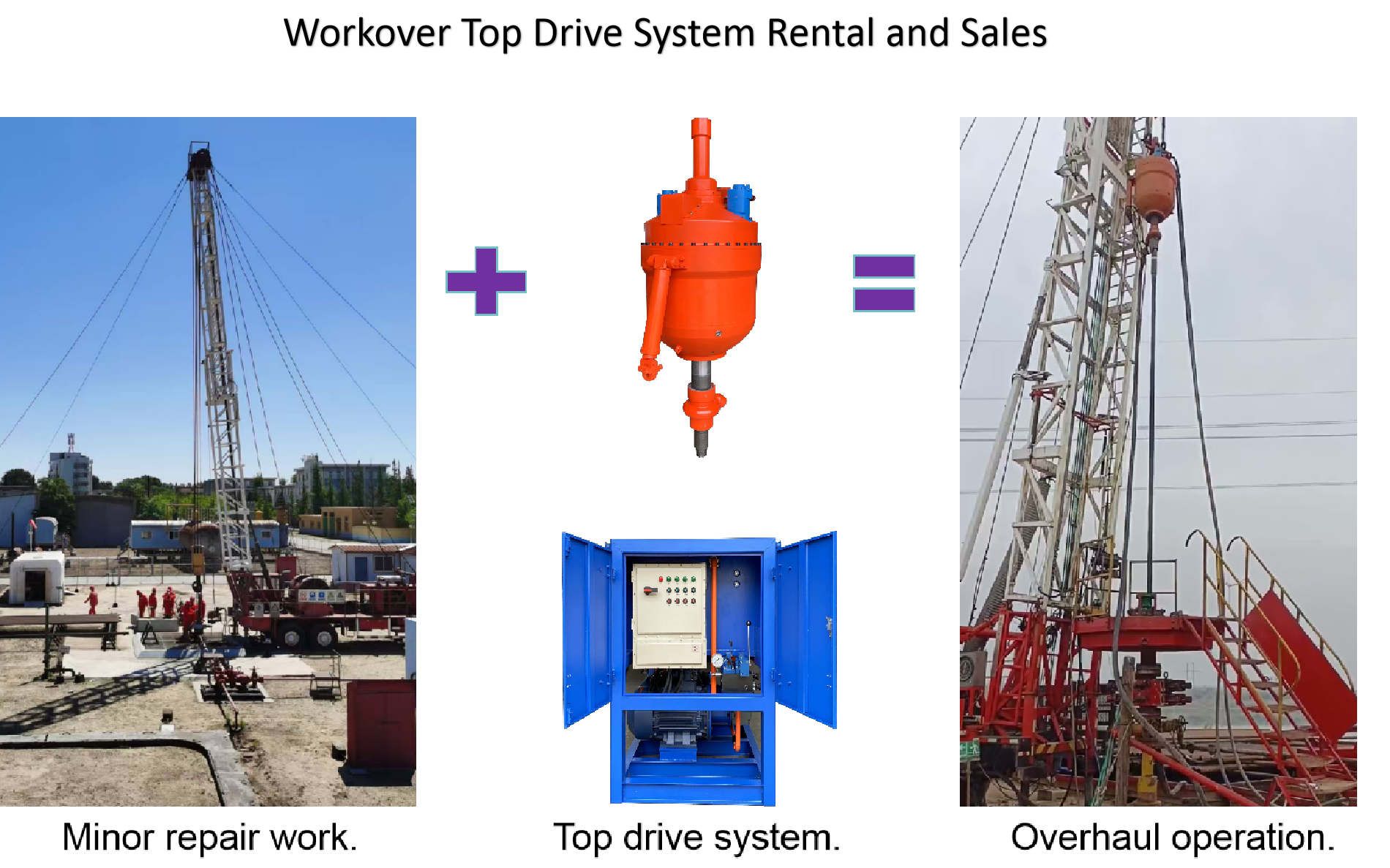

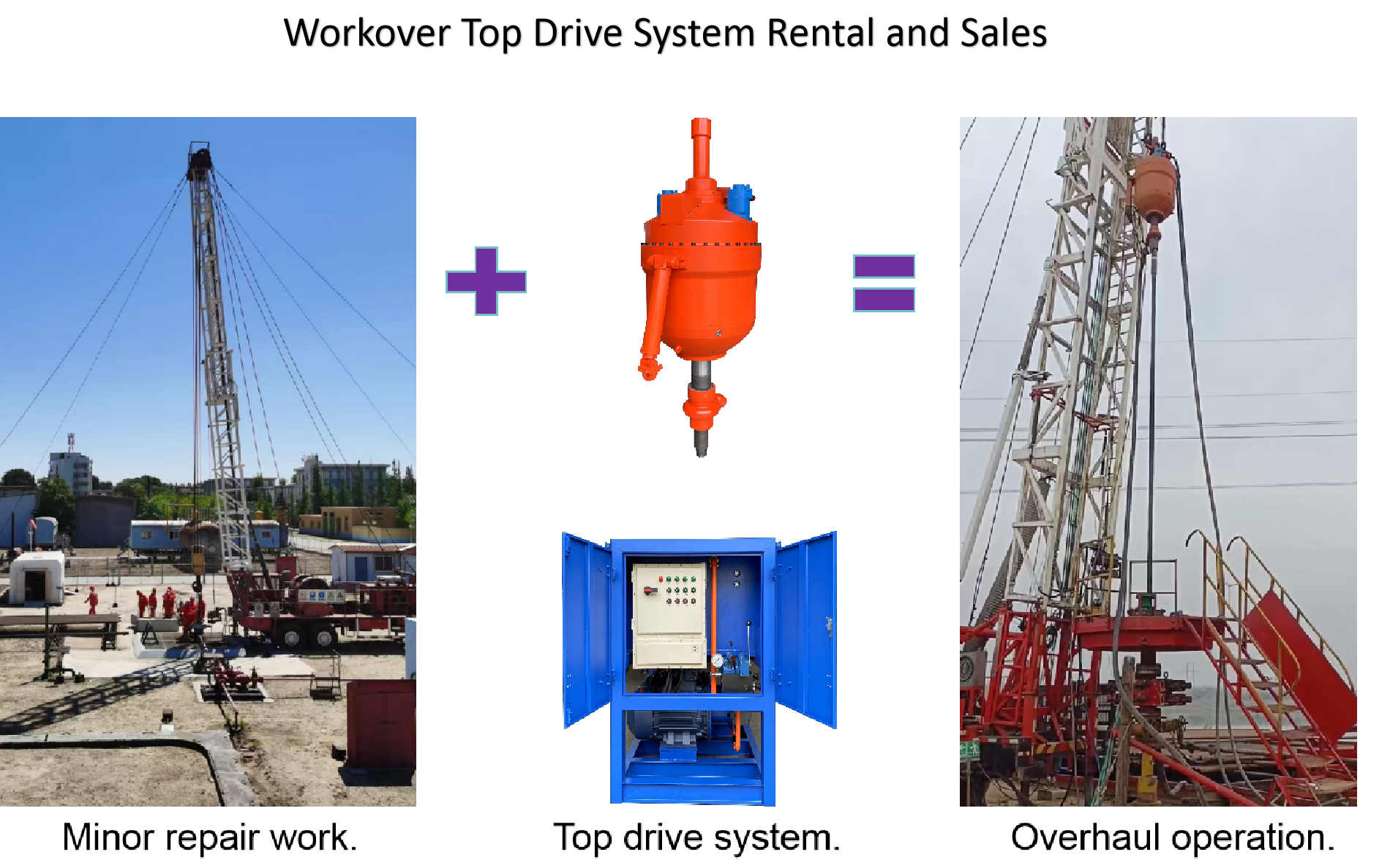

修井顶驱系统租赁及销售

产品技术简介

Product Technology Introduction

Catalog

I. Background Technology

II. Necessity

III. Features

IV. Advantages

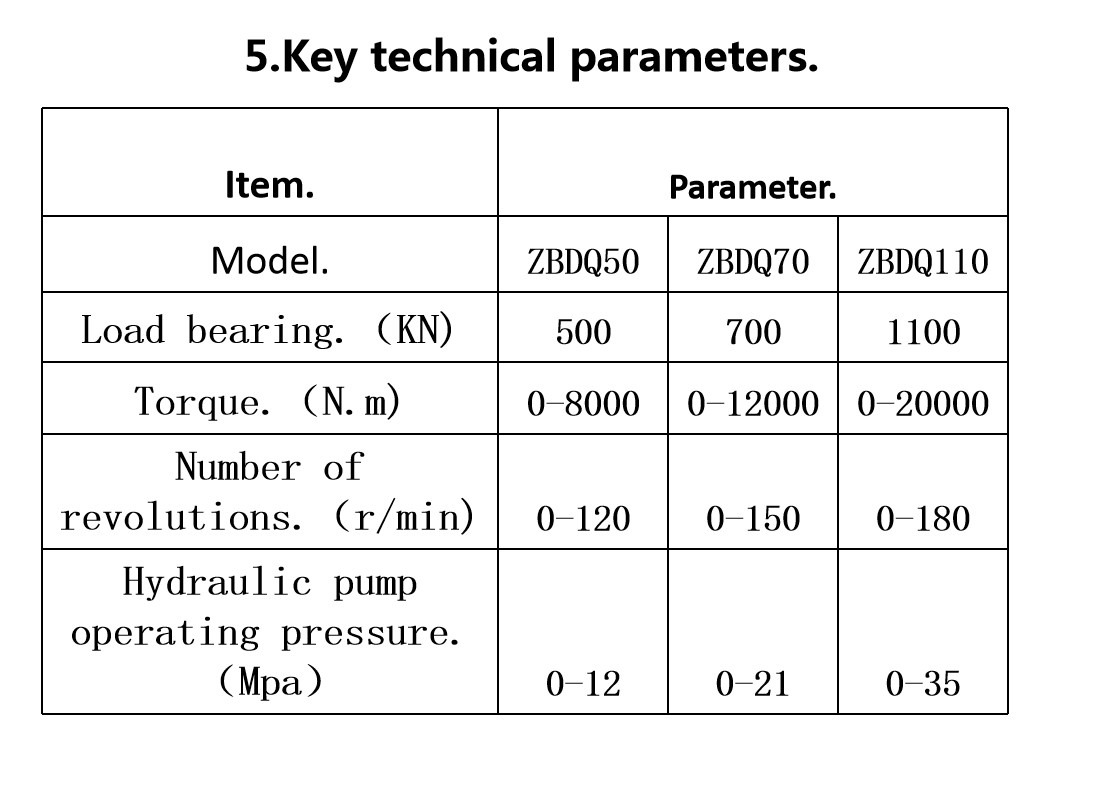

V. Key Technical Parameters

VI. Construction Case

VII. Technical Applications of Top Drive in Workover Operations

VIII. Application Effects of Top Drive in Workover Operations

I. Background Technology

This equipment has been developed against the backdrop of rapid advancements in technologies such as mechanically driven wellhead rotary tables, hydraulically driven wellhead rotary tables, hydraulically driven swivels, mechanically shifted variable-speed power swivels, hydraulic drive drilling top drives, AC/SCR/DC motor-driven top drives, AC frequency-conversion top drives, and AMT (Automated Manual Transmission) automatic-shift variable-speed drive top drives. Our company independently developed the unique technology, the gear meshing transmission automatic stepless speed changer, and successfully applied it to create the Automatic Stepless Variable-Speed Workover Top Drive. Its primary function is to drive the drill string for drilling and workover operations in downhole environments. During operations, it achieves automatic stepless speed adjustment without shutdown when load torque changes. It also features practical functions such as zero-output soft start and soft transmission.

The equipment exhibits excellent constant power characteristics, eliminating the need for power matching calculations. It responds sensitively and timely to speed changes, ensuring high operational efficiency. Its unique zero-output mechanism prevents accidents in the drilling system. The product is characterized by simple structural design, user-friendly operation, cost-effectiveness, safety, and reliability. This technology, independently researched and developed by our company, represents an internationally leading scientific achievement. Notably, breakthroughs in the transmission system have resulted in exclusive patented technology, which has earned two national invention patents and two provincial-level scientific achievement awards.

II. Necessity

Current downhole workover operations have seen improvements in equipment capabilities (including surface circulation systems) and process technologies. However, challenges such as long workover cycles, slow efficiency gains, and technical difficulties persist during field operations:

1. Slow casing deformation repair and poor controllability: Prolonged production in oil wells often leads to casing damage, particularly in heavy-oil wells subjected to multiple rounds of steam injection. This results in casing deformation, fractures, and reservoir damage, rendering the well unproductive. Extended milling period during casing repair increases risks of accidental sidetracking, reservoir destruction, and well abandonment.

2. Limited construction sites in environmentally sensitive areas: Conventional workover rigs struggle to operate in restricted well sites. The workover top drive system addresses this gap, offering a novel construction mode for restricted environments.

3. Challenges in reverse drilling packer operations: Due to reservoir structural complexities, long-term water production in oil and gas wells necessitates reservoir adjustment and redevelopment. During workover operations, original wellbore packers or bridge plugs may need to be drilled out. However, these components (non-drillable in early stages of field development) often remain stuck in the wellbore, necessitating abrasive casing milling. Traditional methods are time-consuming and prone to issues such as prolonged milling, window cutting, and sidetracking.

To resolve these challenges, our company developed the gear meshing automatic stepless variable-speed workover top drive system, applicable to various drilling and workover scenarios, including slim-hole drilling, cement plug drilling, bridge plug drilling, packer drilling, plug drilling, casing milling, core drilling, and casing replacement.

III. Features

1. Wellhead blowout preventer compatibility: A plug valve can be installed below the first drill string joint for instant well closure, ensuring compatibility with well control equipment.

2. Direct use of stands: Reduces tripping time.

3. Simplified design: Eliminates components such as frequency converters, clutches, brakes, synchronizers, gear shifters, load-sharing mechanisms, and constant-speed output mechanisms, reducing energy consumption and operational costs.

4. Zero-output capability: Ideal for operations with frequent load fluctuations, transient high peak power, or impact/sticking risks. In case of sticking, the drill can be lifted immediately for high-speed rotation without releasing drill string torque, preventing tool detachment and ensuring safety for equipment, drill strings, and wells.

5. Constant power characteristics: Automatically reduces speed under high torque and restores high speed under low torque. Drilling speed for cement plugs is several times faster than screw drilling tools.

6. No circulation medium restrictions: No filtration required at the inlet.

7. Low reverse torque: Automatically balanced by the top drive’s internal mechanism, simplifying operation and maintenance.

8. Fully automated operation: Automatic rotation control and make/break functions eliminate manual intervention.

9. Cost-effective integration: Compatible with minor workover rigs, reducing ancillary costs.

IV. Advantages

1. Independent hydraulic and circulation systems: Extends service life and simplifies maintenance.

2. Minimized secondary damage: Prevents sticking accidents, ensures precise milling channels, and facilitates reinforcement.

3. Versatile applications: Effective for threading, fishing, casing deformation repair, and complex workover operations in high-risk or sensitive areas.

4. Conventional pipe compatibility: Enables routine operations with standard drill pipes/tubing and rapid wellbore control to prevent blowouts.

5. Compact and automated design: Reduces crew size, labor intensity, and operational costs.

6. Small footprint: Requires only 15×15 m² for rig setup, ideal for restricted sites.

7. Energy-efficient and eco-friendly: Electric drive compatible with field power grids.

VI. Construction Case

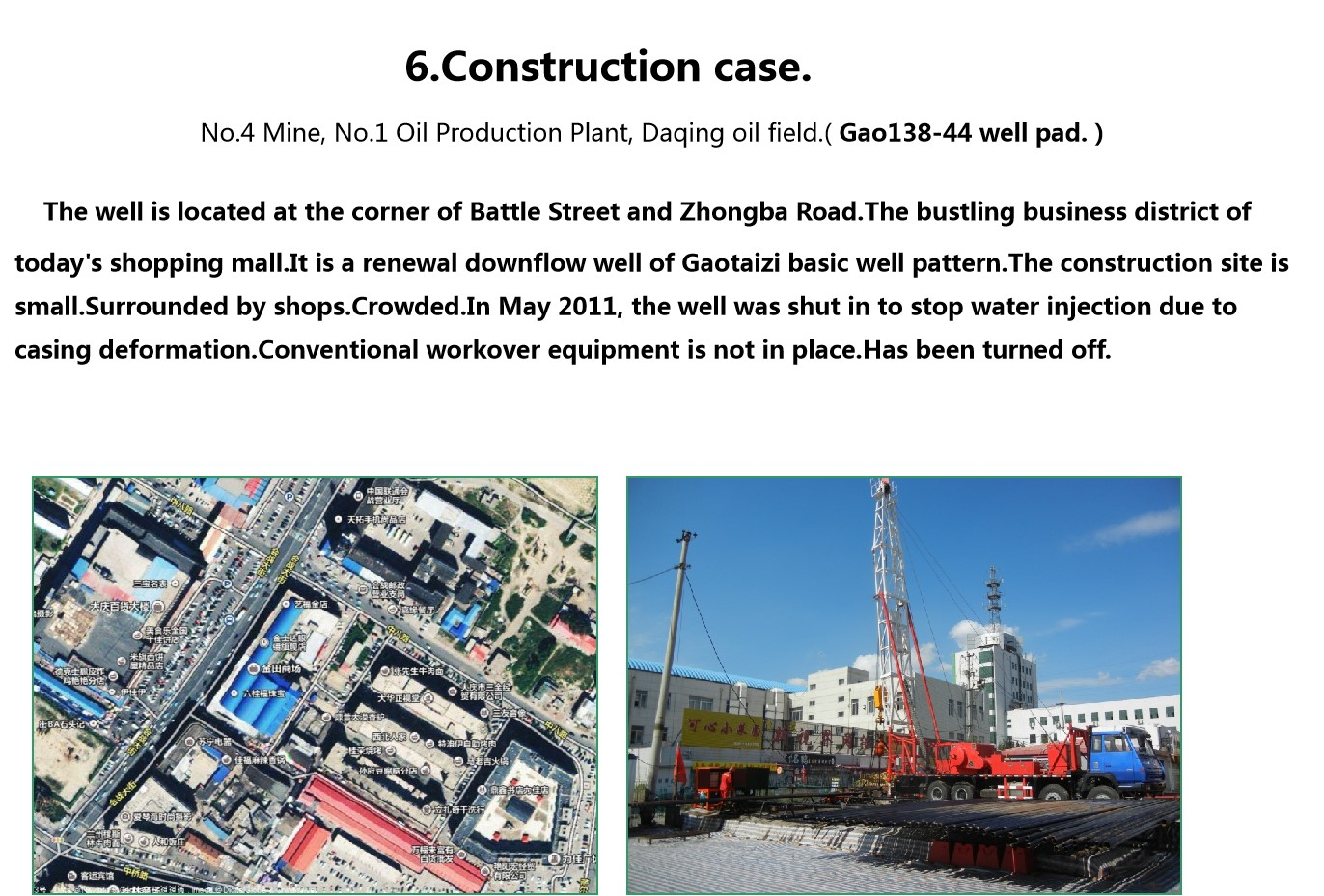

Well Gao 138-Geng 44 (Fourth Mining Area, Daqing Oilfield Production Plant)

Located in a densely populated commercial area at the intersection of Huizhan Avenue and Zhongba Road, this well is part of the Gaotaizi foundational injection network. Shut down in May 2011 due to casing deformation, conventional workover rigs could not access the site.

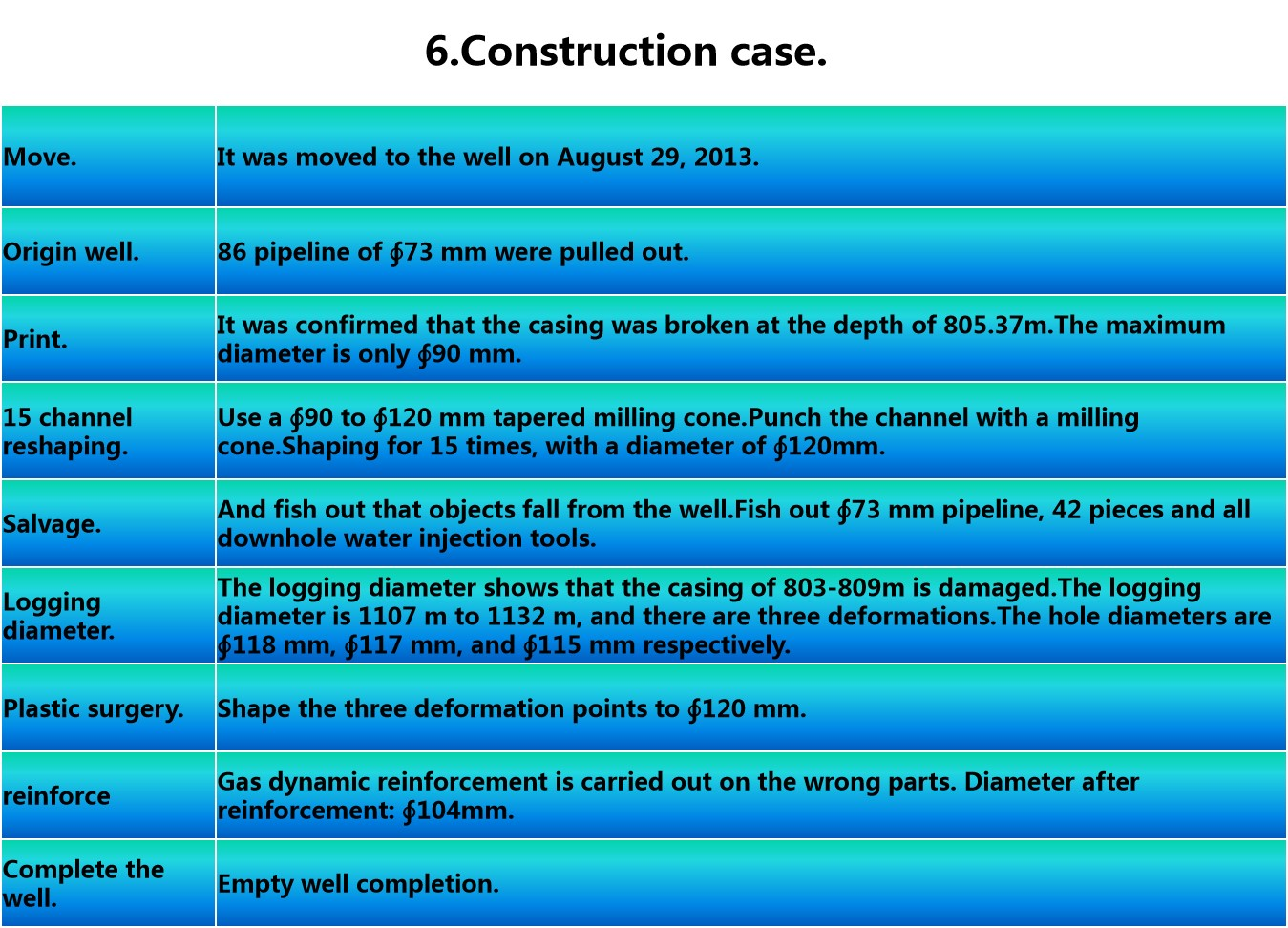

Operations (August 29, 2013):

- Lead impression test: Confirmed casing shear at 805.37 m with a maximum inner diameter of ∅90 mm.

- Channel milling and reshaping: Performed 15 passes with a ∅90–120 mm pear-shaped mill to achieve ∅120 mm.

- Fishing: Retrieved 42 ∅73 mm tubing strings and downhole injection tools.

- Caliper logging: Identified three deformation points (118 mm, 117 mm, 115 mm) between 1132–1107 m.

- Reshaping: Expanded deformations to ∅120 mm.

- Reinforcement: Gas-powered reinforcement at shear point, final inner diameter ∅104 mm.

- Completion: Empty wellbore completion.

VII. Technical Applications of Top Drive in Workover Operations

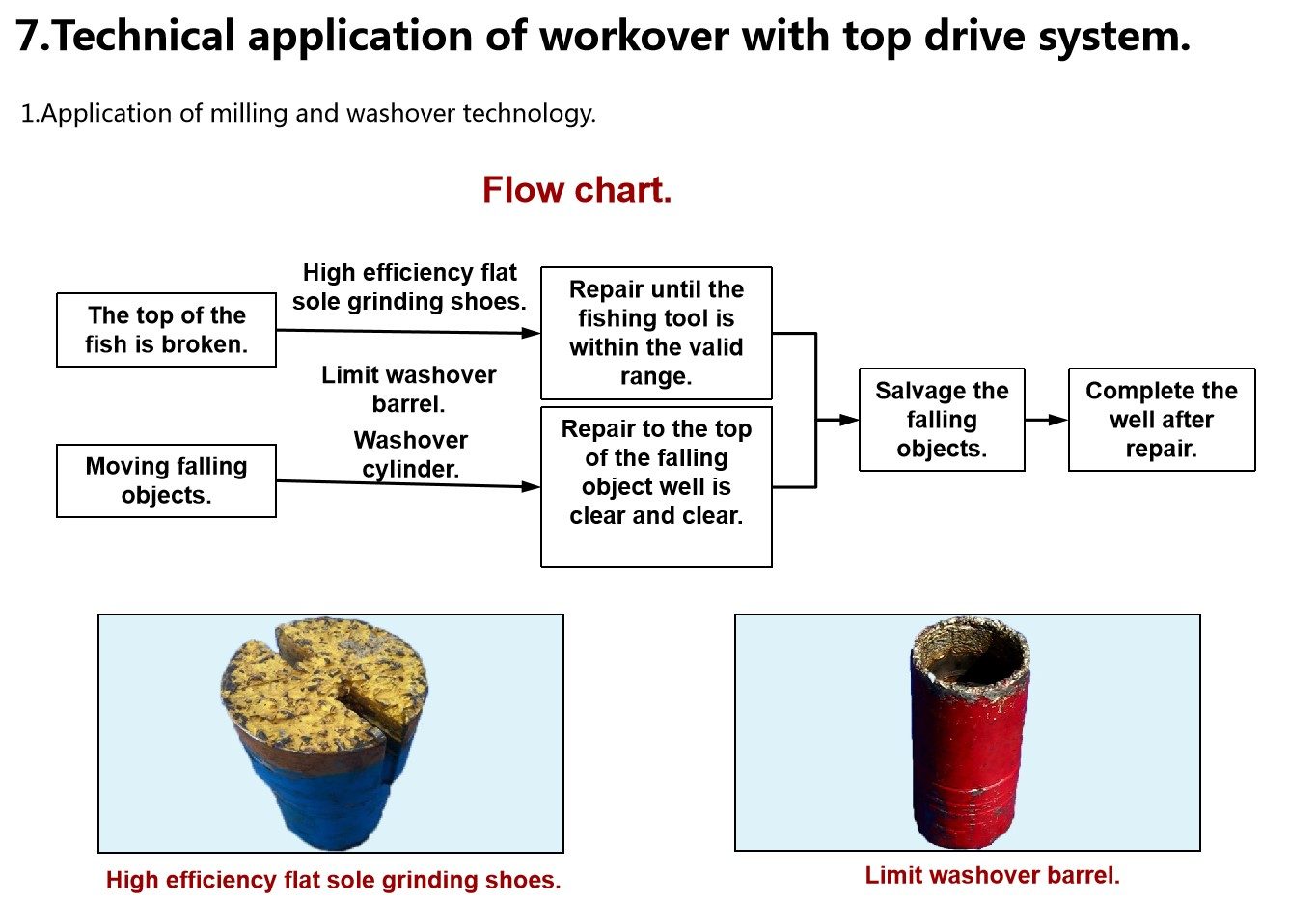

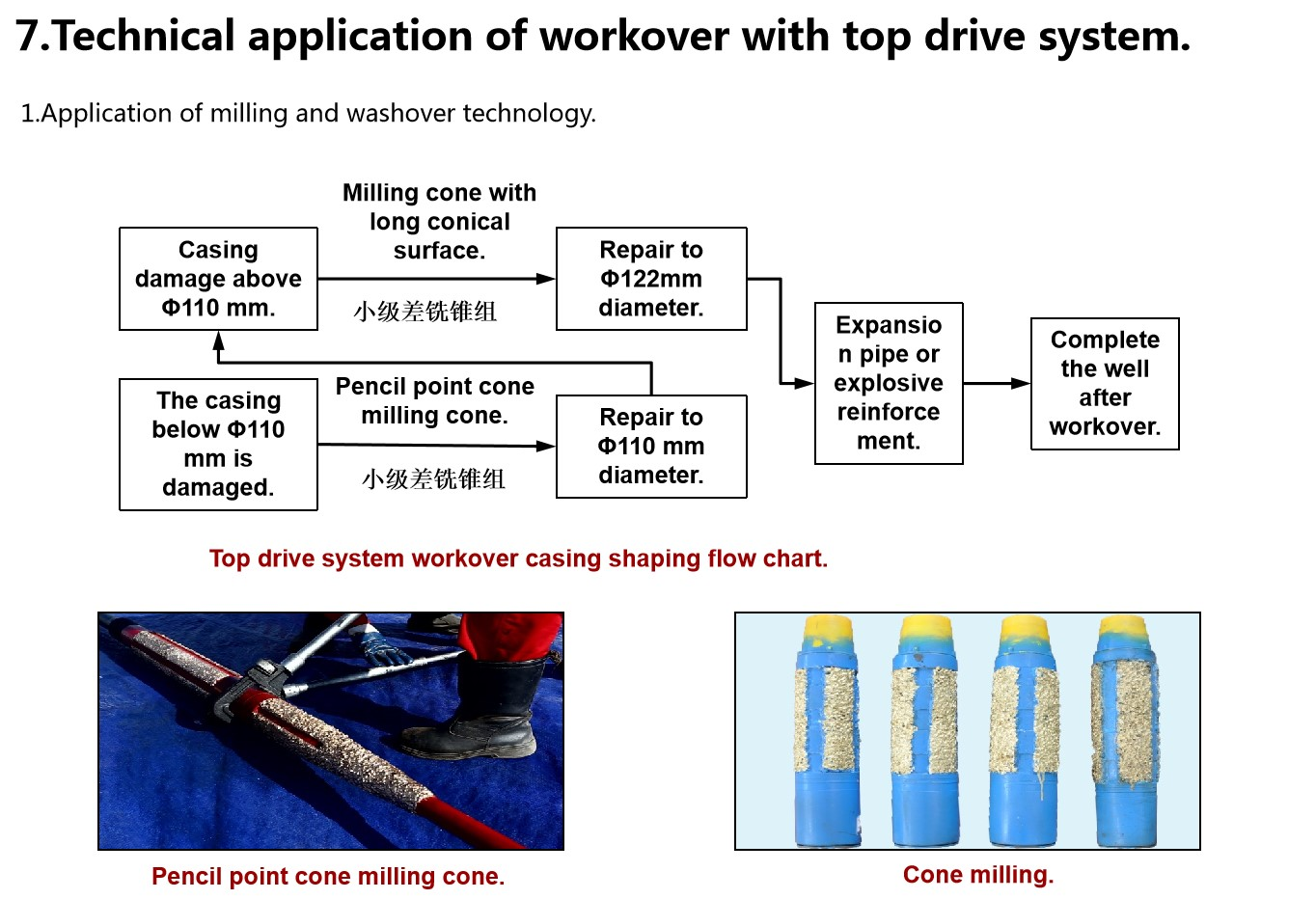

1. Milling and casing milling

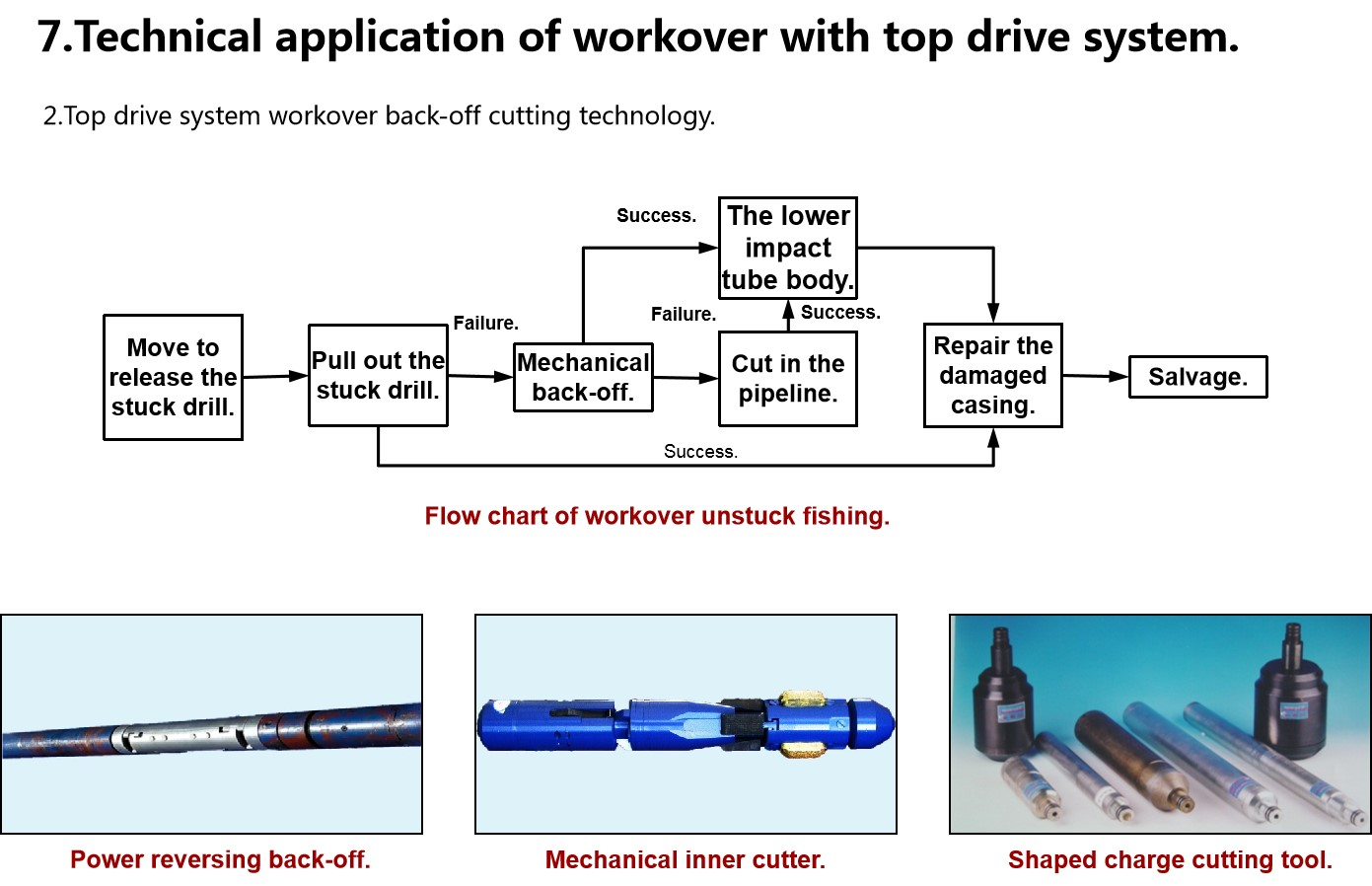

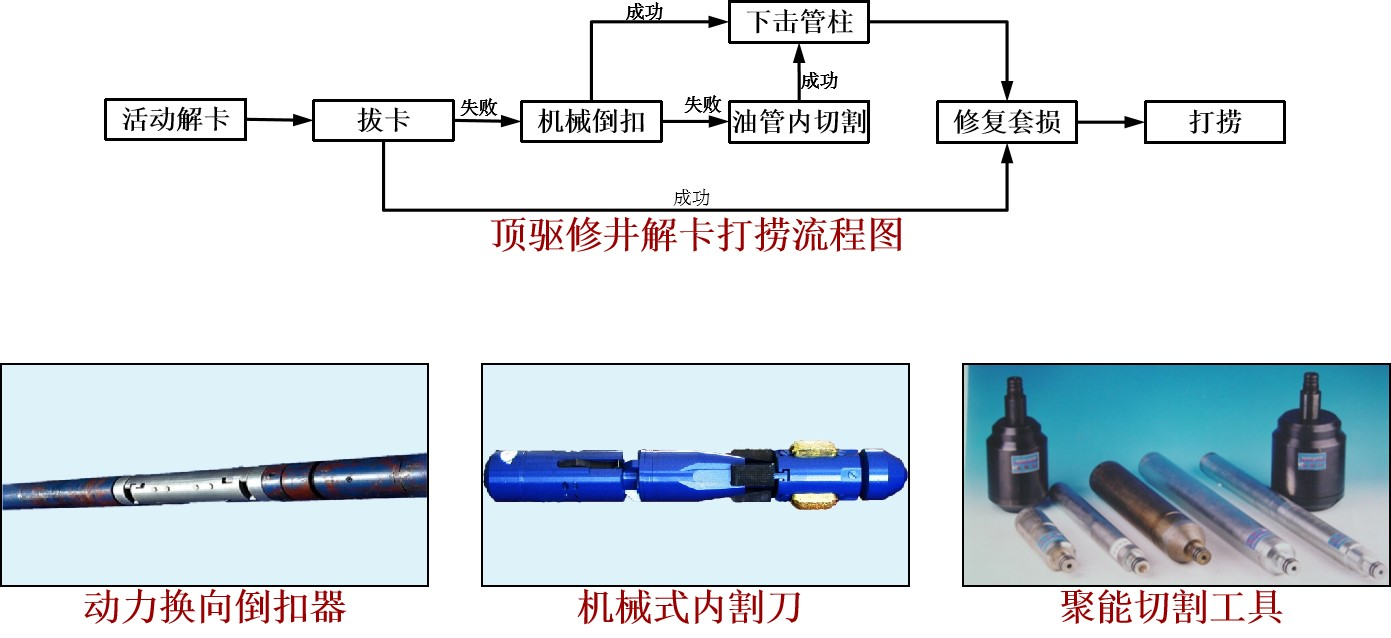

2. Back-off and cutting

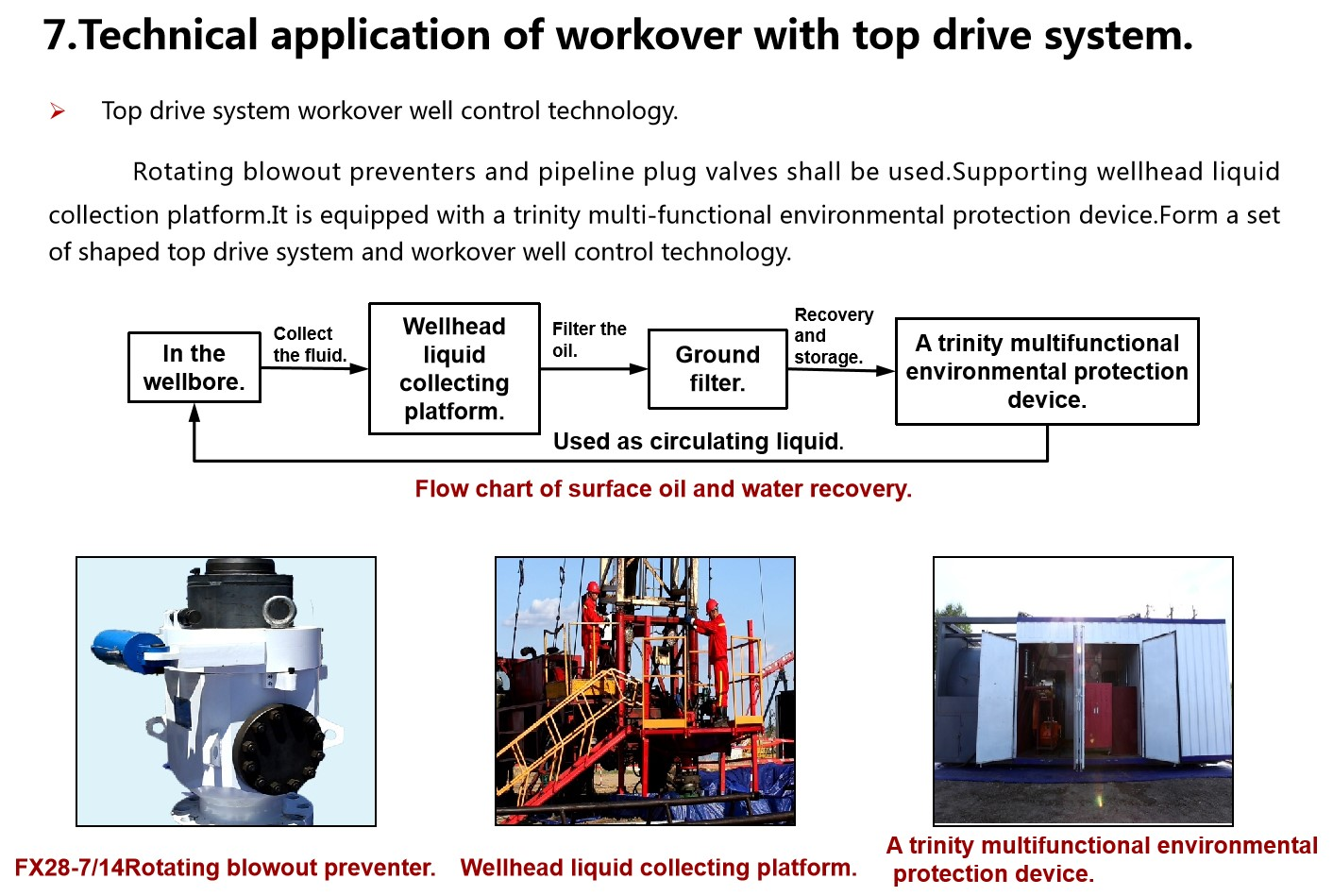

3. Well control

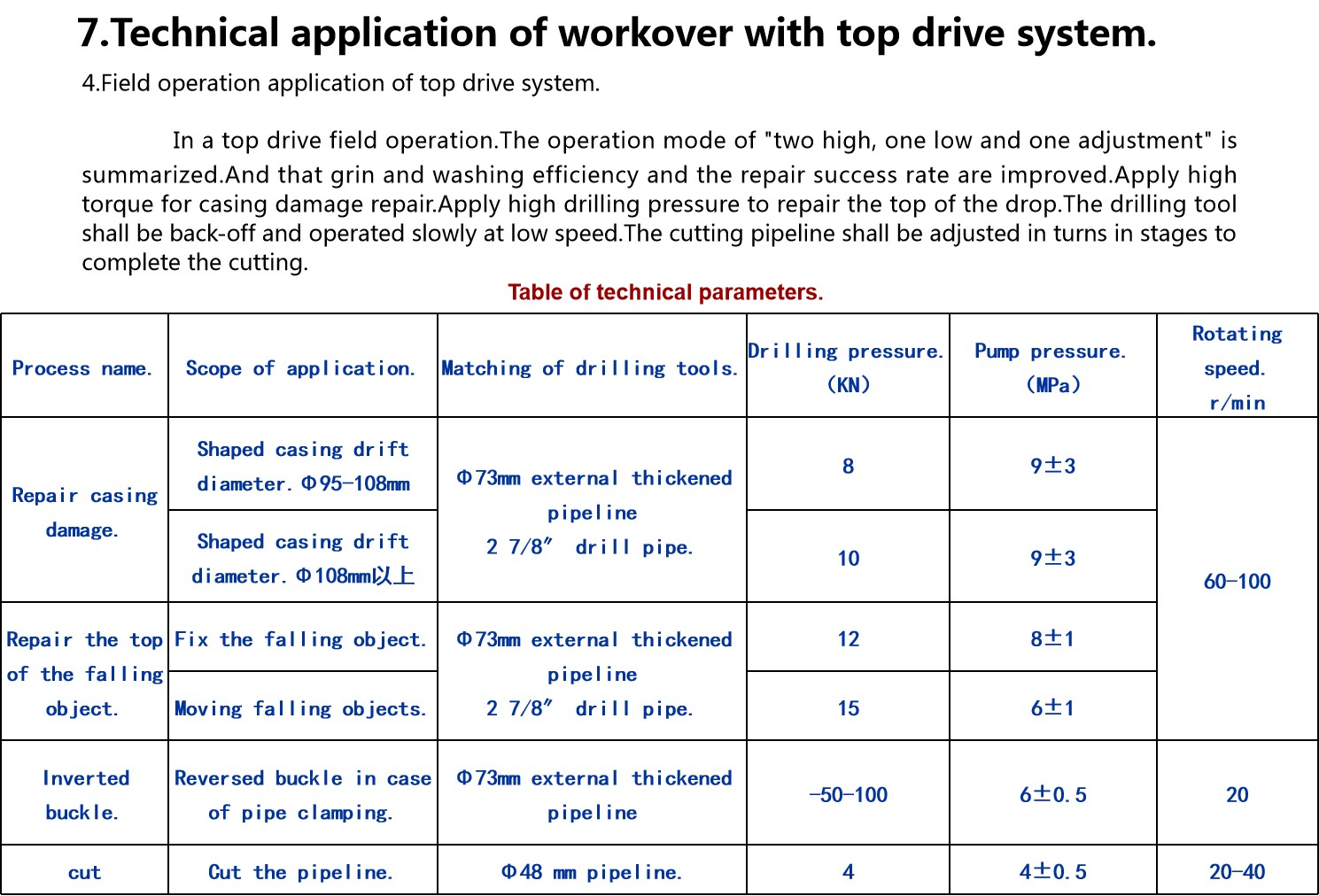

4. Field operation and technology promotion

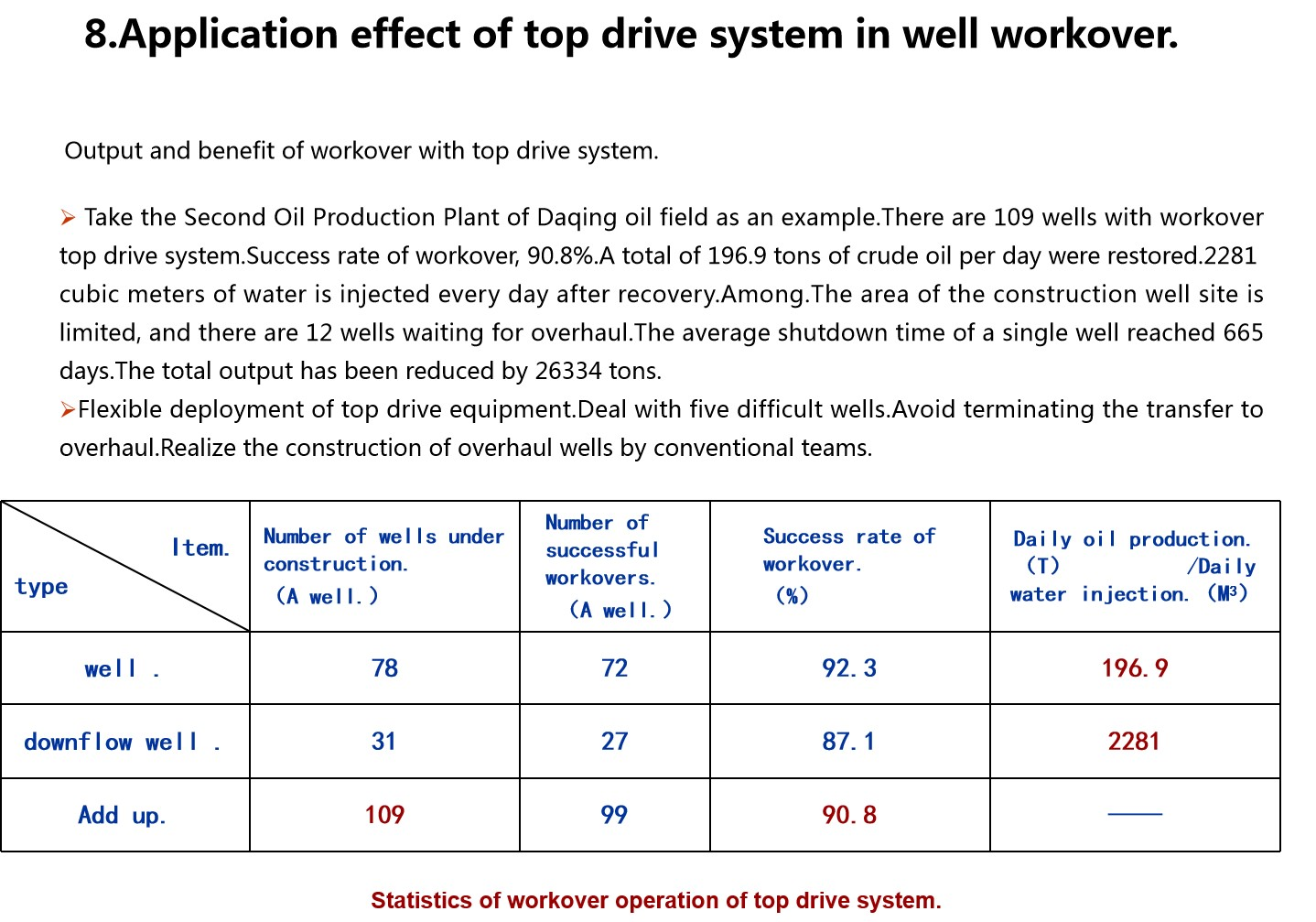

VIII. Application Effects of Top Drive in Workover Operations

Panjin Shunsheng Petroleum Technology Co., Ltd.

March 22, 2025

附件:中文版

修井顶驱系统租赁及销售

产品技术简介

一、背景技术

二、必要性

三、特点

四、优势

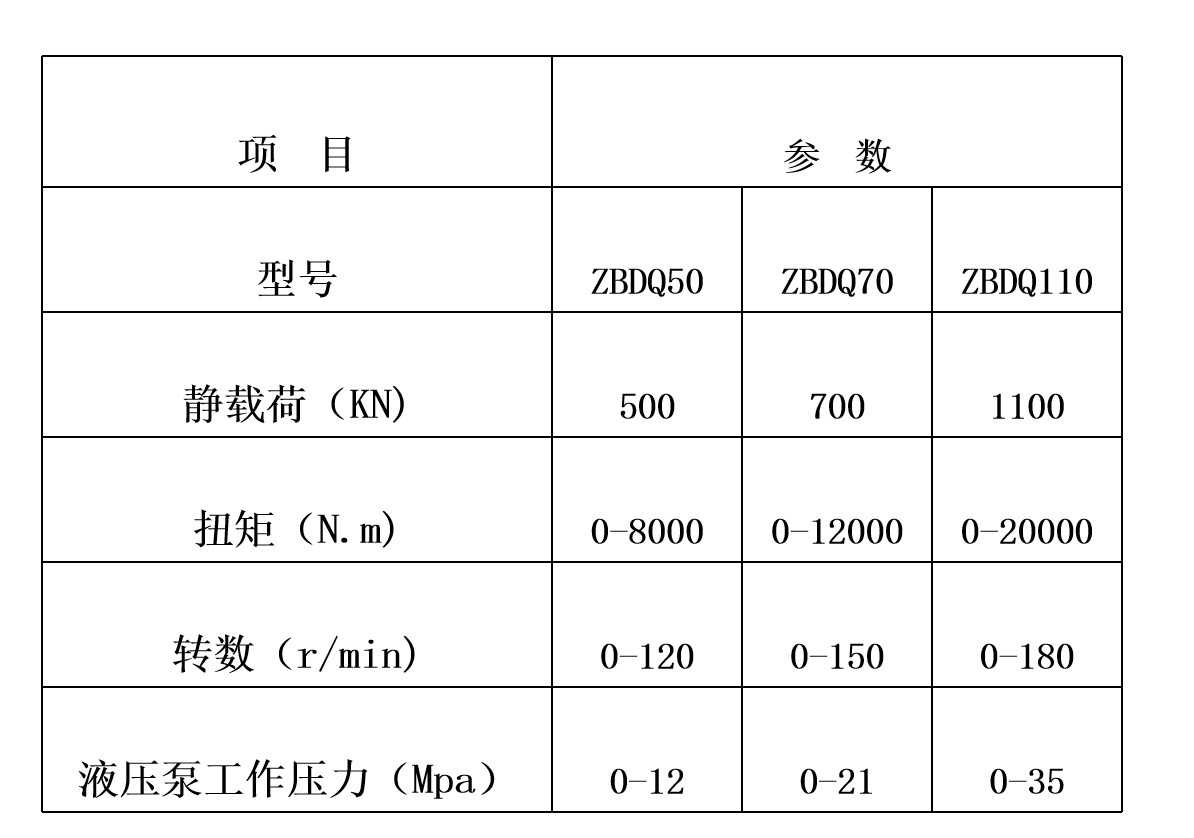

五、关键技术参数

六、施工案例

七、顶驱修井的技术应用

八、顶驱修井的应用效果

一、背景技术

本机是在机械传动井口转盘、液压传动井口转盘、液压驱动水龙头、机械换挡变速动力水龙头、液压驱动钻井顶驱、AC-SCRC-DC直流电机传动顶驱、AC变频顶驱、AMT自动换挡变速传动顶驱等形式的技术、质量、种类和数量方面迅速发展的情况下,本公司自主研发了世界独有技术——齿轮啮合传动自动无级变速器,用该技术成功研制出自动无级变速修井顶驱。其主要是驱动钻柱在井下进行钻井、修井作业。并在作业过程中,在负载扭矩变化时不停机,实现自动无级变速。并具备有零输出、软启动、软传动等实用性功能。

还具备恒功率特性好,不需计算配带功率,变速灵敏及时、适时,作业效率高,独特的零输出机构使钻具系统不出事故,结构简单、操作方便、经济可靠等特性。该项技术是本公司自主研发的具有国际领先水平的科研成果,尤其是传动系统在国际上有重大突破,属独有技术。以获得两项国家发明专利和两项省科技成果奖。

二、必要性

目前井下大修作业在设备能力(含地面循环系统)和工艺技术上得到保障和进步,但修井周期较长,提质提速较慢,现场实际施工过程中存在一些技术难题。

一、修理套管变形速度慢,控制难度大。油井长期生产,套管在井里容易受损,特别是稠油井经过多轮次注汽导致套管变形、错断较多、油层被破坏无法生产。大修修套时磨铣时间长,易导致磨铣工具将套管开窗侧钻出去,破坏层系,油井报废。

二、环境敏感区的油水井施工井场受限制难题,修井顶驱弥补了常规大修无法开展受限井施工的缺失。是一种全新的大修施工模式。

三、油层下返钻封隔器施工难度较大

受油层构造影响,油井生产几年或一段时期长时期出水,需要上措施调整层系,实施下返油层生产,大修作业时需要钻掉原井封堵的封隔器或桥塞,油田开发初期封隔器及桥塞不是可钻的,长期卡在井筒内,无法实施打捞,就得采用磨、铣、钻的修井方式,在实施钻封过程中受磨铣工具、钻柱、钻压、旋转转盘的影响磨铣时间长,也会导致开窗侧钻。为了解决上述问题,采用本公司独有技术开发研制出齿轮啮合自动无级变速大修井顶驱。可广泛应用于各类钻修井场合。包括钻小眼井、钻水泥塞、桥塞、封隔器、堵塞器、套铣、铣磨、钻取岩心、取换套大修等作业。

三、特点

1、井口可安装防喷器,钻柱第一根下面连接旋塞阀可随时实

现关井,适应井控装置的使用。

2、本机直接采用立根作业,节省钻柱起下时间。

3、结构简单,本机无变频器、离合器、制动器、同步器、换挡器、齿轮均载机构和等速输出机构等等,节省能源和作业资金。

4、本机有零输出功能,适用于载荷变化频繁,峰值功率高而

短暂,有冲击、卡阻、卡钻等场合,在出现卡堵时可立即提钻,恢复高速旋转,不用释放钻柱扭矩,不会使钻柱脱扣落井。对作业设备、钻具系统和油井均有安全保护作用。

5、本机恒功率特性好,负载扭矩大时,转速自动降低,负载

扭矩小时,自动恢复高转速。自动变速灵敏,钻水泥塞时比螺杆钻具进尺速度提高几倍。

6、不受循环介质限制,进口不需过滤。

7、本机工作时反扭矩很小,主要由顶驱内部机构自动平衡掉,

8、操作简单、使用维修方便,开机后钻柱旋转工作的一切变

化均由本机自动进行,自动上卸扣不用人工控制,自动上卸扣方便。

9、用小修作业机配合,节省了配套费用。

四、优势

1、顶驱液压系统和循环系统各自独立运行,互不影响循环介质不受限制,延长使用寿命,方便维修。

2、次生伤害小不会出现卡钻事故,磨铣通道规则,校直精确度高,便于加固施工,。

3、能很好完成造扣打捞、套损打通道、套变修整及井场受限高危敏感区复杂大修井施工等。

4、利用常规油管、钻杆作业,便于井控,不会发生失控现象。

5、产品结构紧凑,自动化程度高,施工操作简单与常规大修队伍相比员工数量少,劳动强度低。

6、利用现有小修设备,增加一台修井顶驱,即可实现两只以上小修队伍具备大修施工能力。

7、体积小重量轻,配套无绷绳修井机井场面积达到15×15㎡既可开展大修施工,运行成本低,配套设备数量少,班家成本低。

8、无需导轨或磞绳平衡反扭矩,顶驱内部平衡机构能自动平衡掉反扭矩。

9、电力驱动,可与井场用电匹配,节约能源,实现环保作业。

五、关键技术参数

六、施工案例

高138-更44(大庆采油一厂四矿)

该井位于会战大街与中八路夹角处,金田商场与力佳广场中间的繁华商业区,为高台子基础井网的一口更新注水井,井场狭小,周围商铺环绕,人员密集。 2011年5月该井因套管变形关井停止注水,常规修井机无法就位,一直处于关井状态。

作业队于2013年8月29日就位该井,打铅模证实一处套管错断,最大通径∮90mm。锥铣打通道、整形15次至通径∮120mm,捞出井下落物。测16臂井径显示错断点套损大于∮140mm,1132-1107m共有三处变形118mm、117mm、115mm,整形三处变形点至∮120mm,对错断部位进行燃气动力加固,正常完井。

搬家: 2013年8月29日搬家至该井就位。

起原井: 起出∮73mm油管86根。

打印: 证实套管在深度:805.37m错断,最大通径仅有∮90mm。

打通道整形15次:使用∮90-120mm梨形铣锥,锥铣打通道,锥铣整形15次至通径∮120mm。

打捞: 捞出井下落物: ∮73mm油管42根及井下全部注水工具。

测井径:测16臂井径显示803-809m套损1132-1107m共有三处变形118mm、117mm、115mm。

整形: 整形三处变形点至∮120mm。

加固: 对错断部位进行燃气动力加固,加固后通径∮104mm。

完井: 空井筒完井。

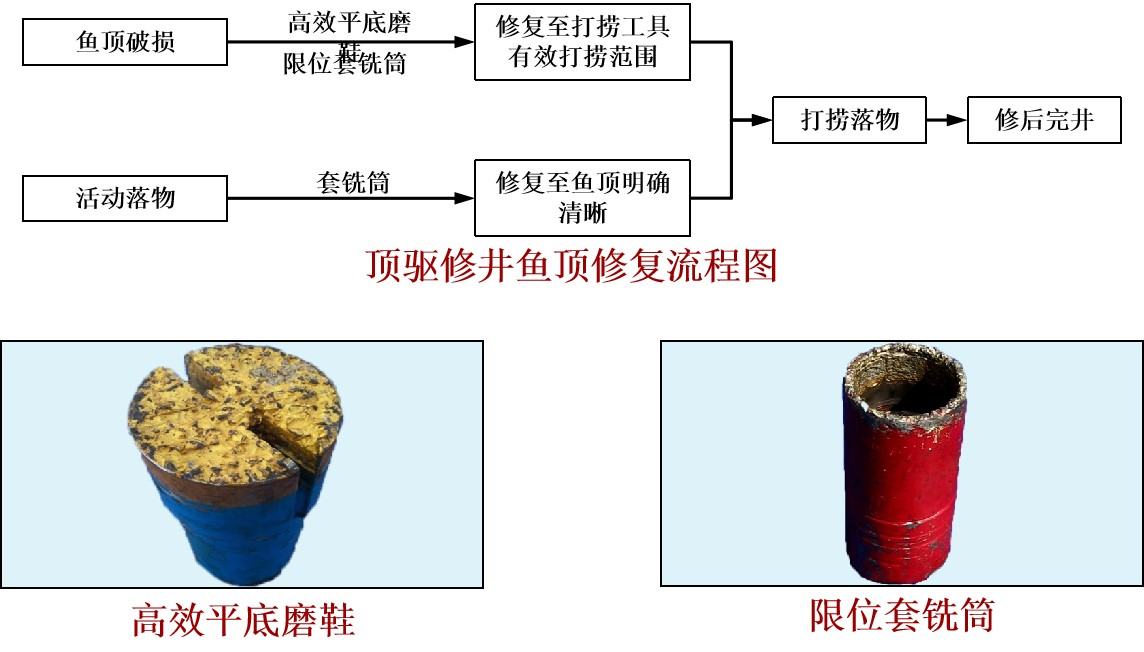

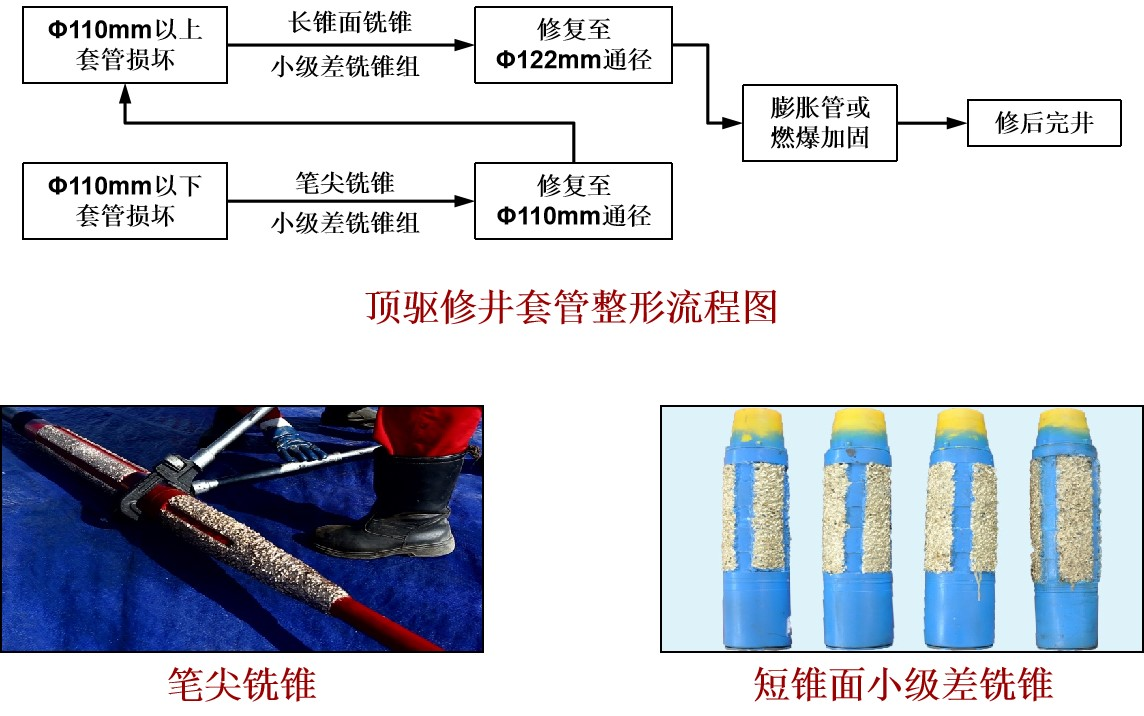

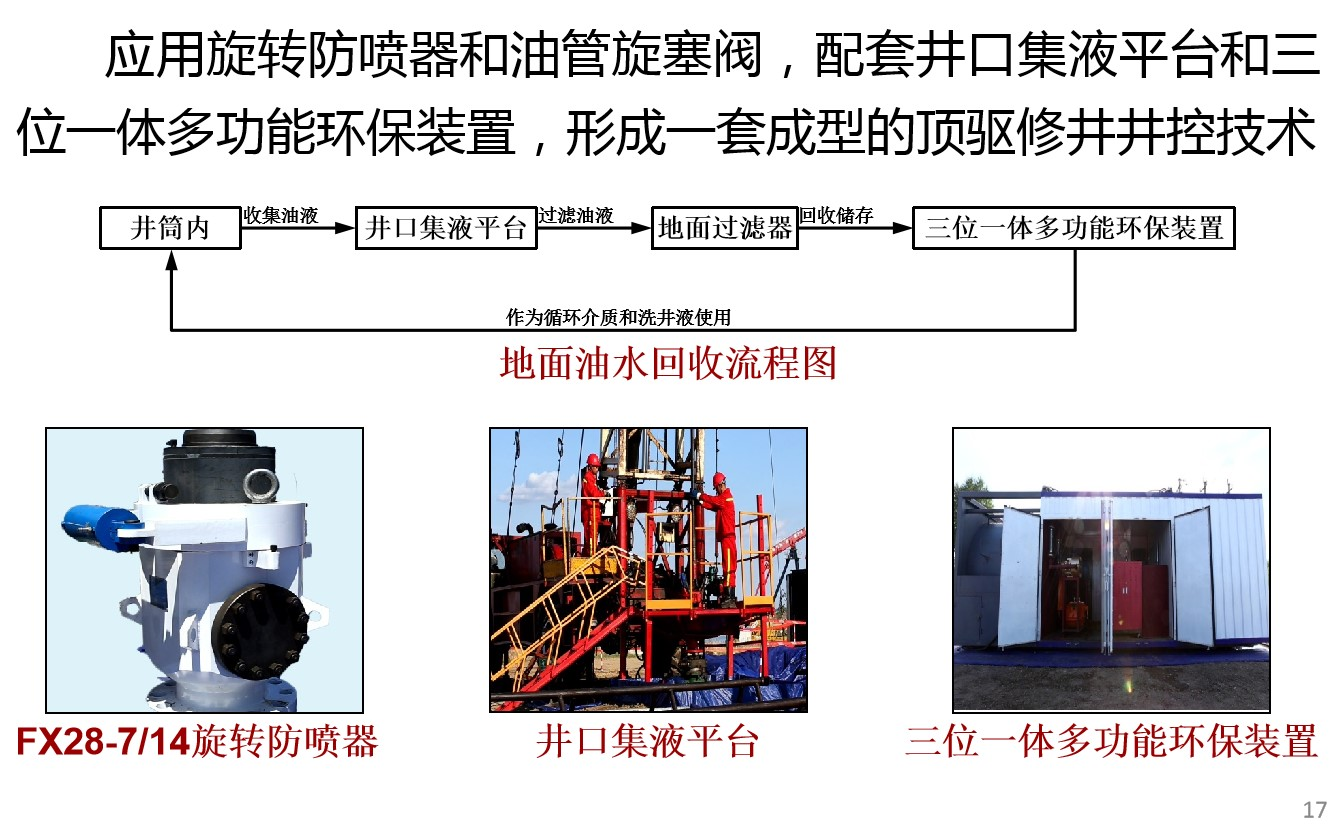

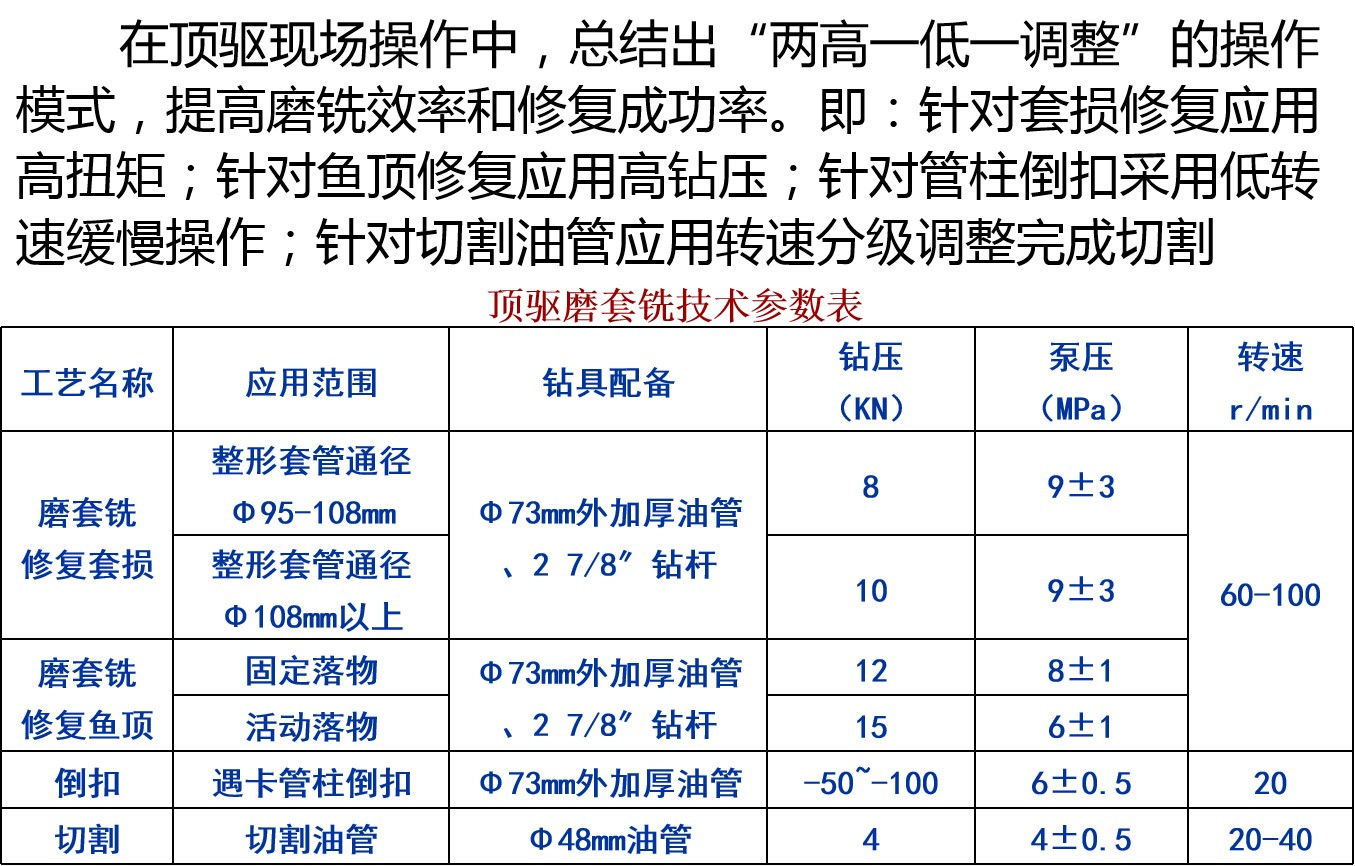

七、顶驱修井的技术应用

磨铣、套铣技术应用

2、顶驱修井倒扣切割技术

3、顶驱修井井控技术

4、顶驱修井现场操作应用技术推广

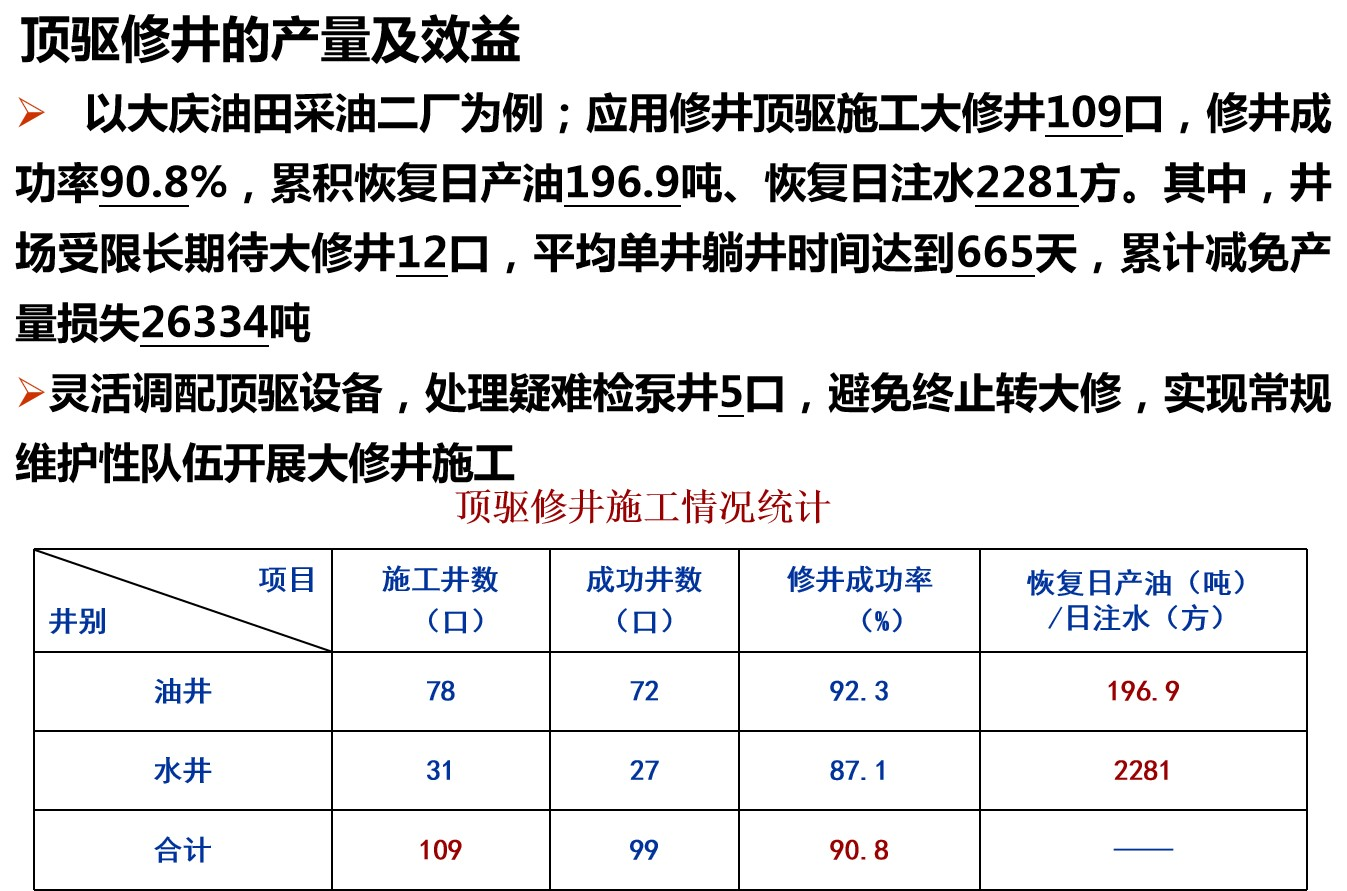

八、顶驱修井的应用效果

Panjin Shunsheng Petroleum Technology Co., Ltd.

2025.3.22